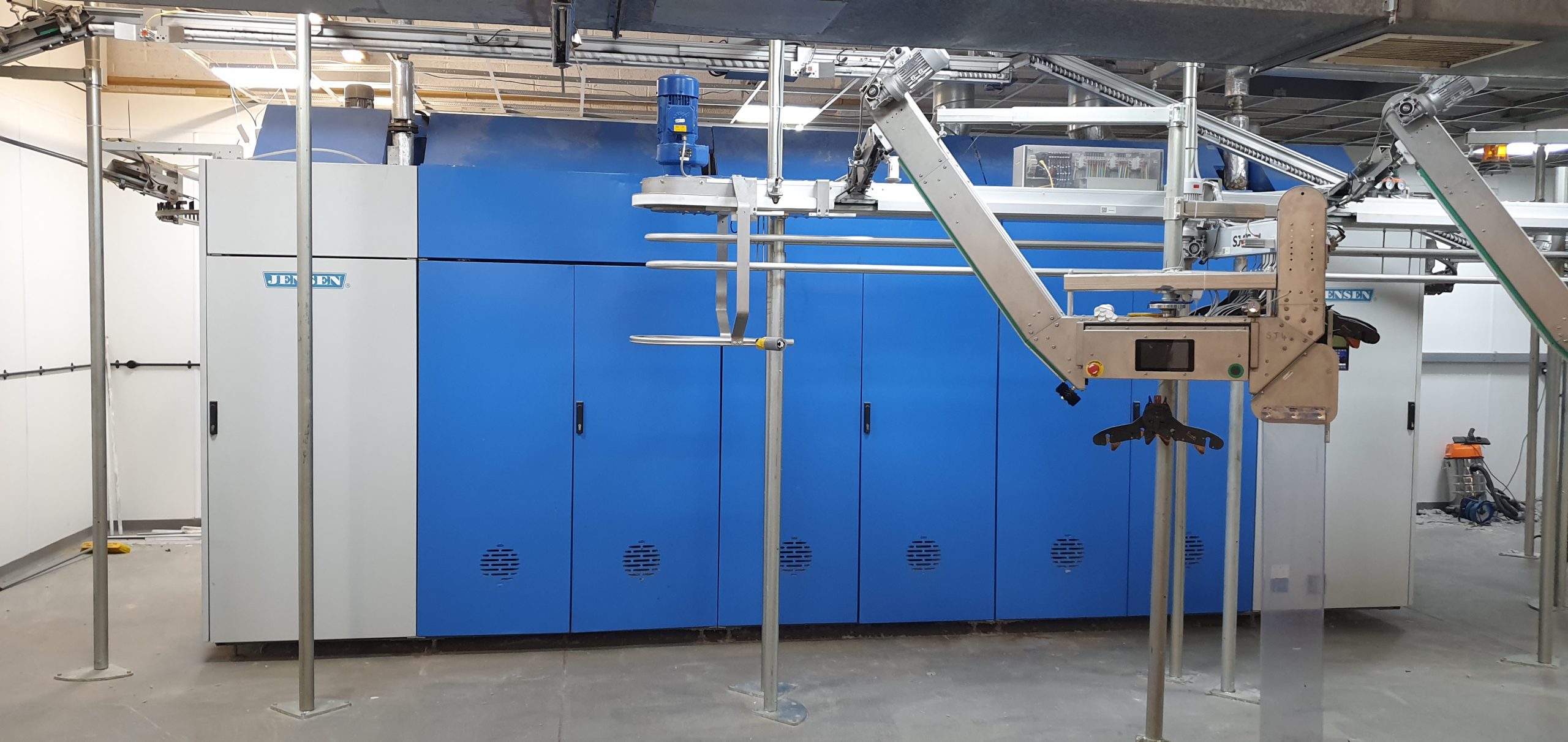

A complete garment tunnel finishing system comprising:

3 x DVT Superjet automatic garment loading systems. Utilising the Jensen “lobster” collapsible hanger format, these three loading stations transport loaded hangers onto the main transport conveyor leading to:

1 x Jensen Omega 3S, steam heated garment tunnel finishing system. Fully rebuilt in 2016 this steam heated machine has a capability of around 600 – 700 garments per hour. This discharges to an out-take rail leading to a fully automated garment folding system from Biko Laundry Systems, comprising:

1 x Kuka (Supplied by Biko) Robotic arm. This automatically unloads garments from the hangers places garments on the in-feed nose of the garment folding machine

1 x Biko Lauren, automatic garment folding machine, automatically french-folds and makes up to two cross-folds (knife and reversing belt execution), before stacking on a discharge conveyor at the rear.

The whole system is in excellent condition and was supplied brand-new in 2016. It is available immediately. Please contact us for further details.